The Anatomy of a Wiring Harness: Components, Functions & Common Configurations

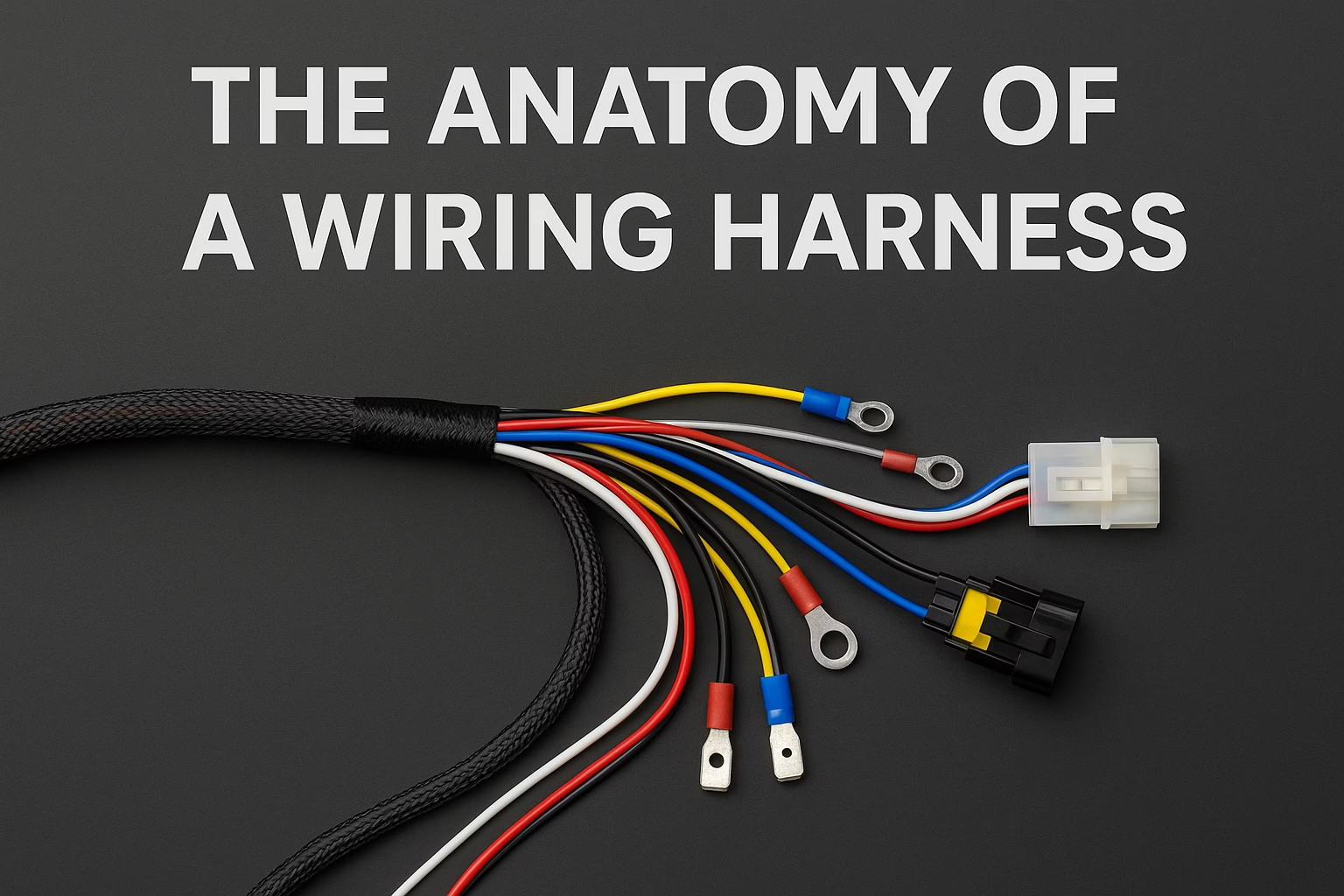

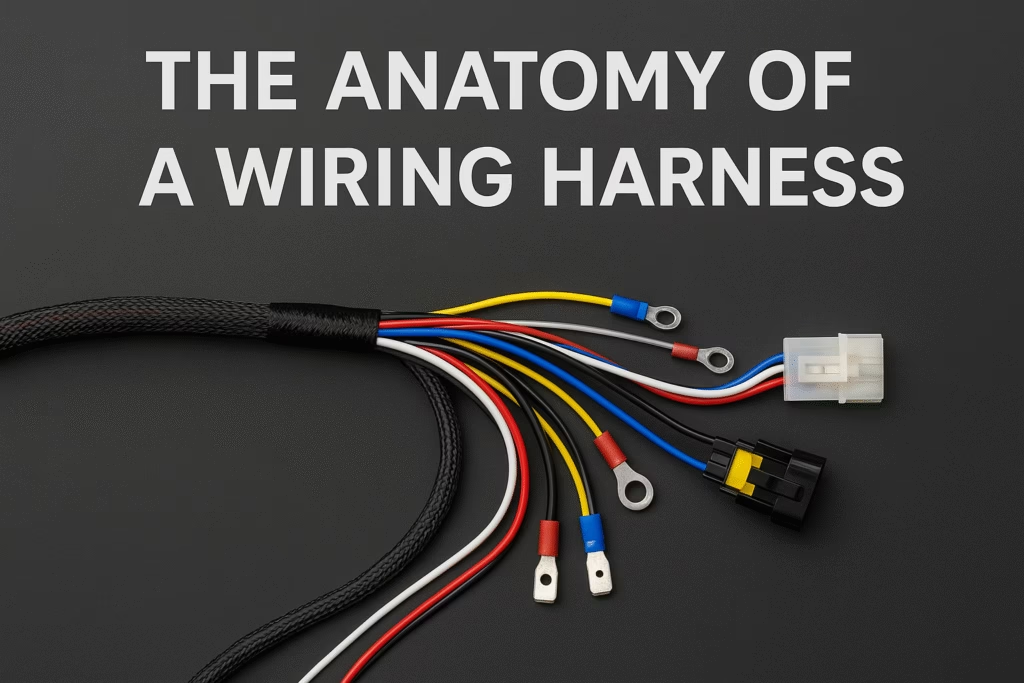

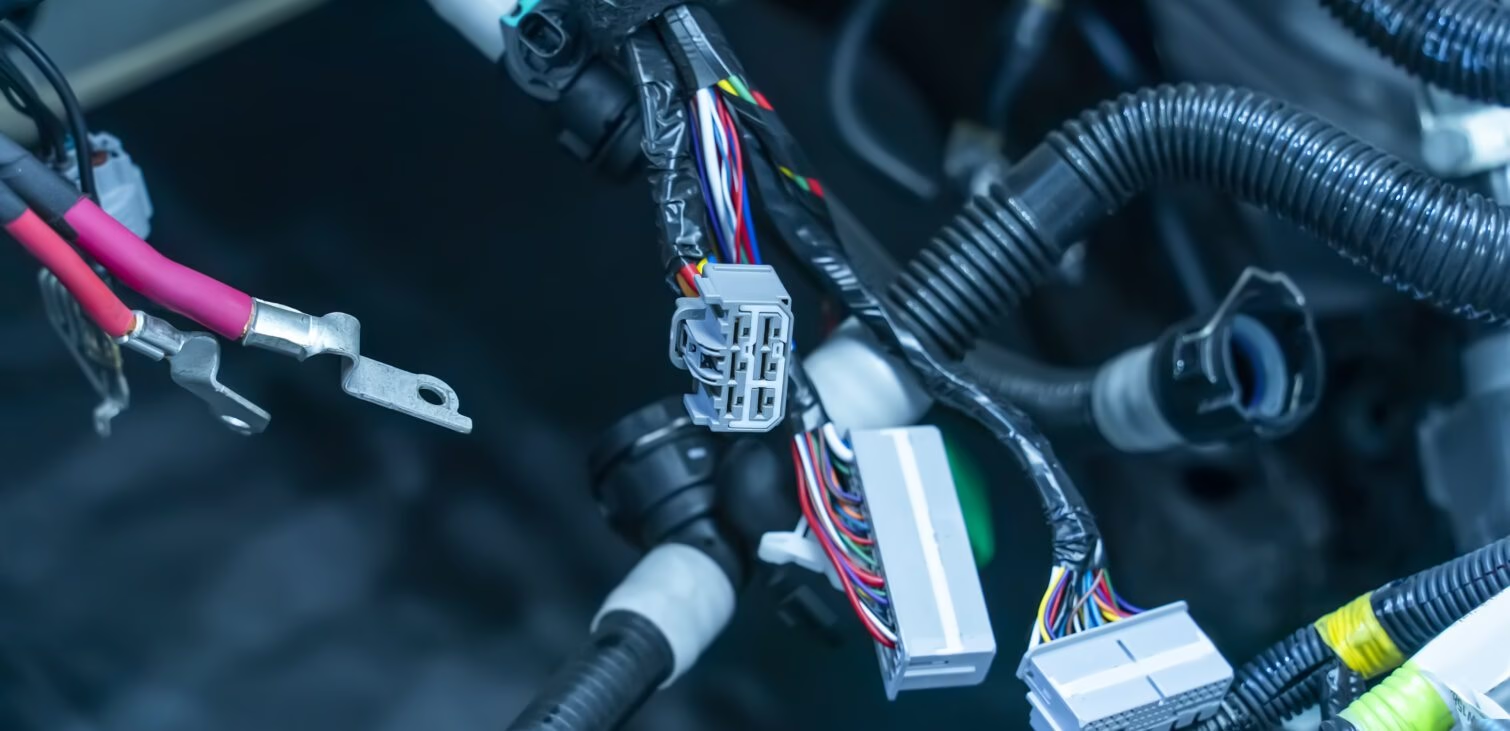

When it comes to powering critical electrical systems—be it switchgear, control panels, or complex automotive equipment—the wiring harness is the unsung hero. It might look like a bundle of wires, but in reality, it’s a highly engineered system that ensures safe, reliable, and organized power and signal distribution.

In this article, we’ll break down the anatomy of a wiring harness, explaining its core components, functions, and common configurations used across industries.

What is a Wiring Harness?

A wiring harness, also called a wire harness or cable assembly, is an organized set of electrical wires, terminals, and connectors that transmit power and signals within a device or system. These components are bound together by durable materials like tape, sleeves, conduit, or overmolded sheathing to withstand environmental and mechanical stress.

Key Components of a Wiring Harness

Each wiring harness is custom-built based on application, but the fundamental components include:

1. Wires & Cables

-

Function: Carry electrical current or data signals.

-

Materials: Typically copper or aluminum, with insulation made from PVC, XLPE, or Teflon depending on temperature and voltage requirements.

-

Specifications: Wire gauge (AWG), voltage rating, and insulation type are tailored to the application.

2. Connectors

-

Function: Join wires to devices or other wires.

-

Types: Blade, ring, spade, or multi-pin connectors based on mating type and current capacity.

-

Importance: High-quality connectors reduce resistance, improve reliability, and support plug-and-play functionality.

3. Terminals

-

Function: Provide the endpoint for electrical contact.

-

Materials: Brass, copper, or tin-plated terminals designed for crimping or soldering.

-

Application: Securely connect wires to switches, circuit breakers, or relays.

4. Sleeves & Looms

-

Function: Bundle and protect wires from heat, abrasion, and moisture.

-

Types: Braided, convoluted tubing, fabric wrap, or heat shrink.

-

Benefit: Enhances cable management and improves serviceability.

5. Tapes, Clamps & Labels

-

Function: Hold the harness together, anchor it in place, and provide identification.

-

Labelling: Laser-etched or printed tags for wire codes, voltage ratings, and part numbers help during installation and maintenance.

Functions of a Wiring Harness

A professionally designed wiring harness serves several mission-critical functions:

Power Distribution: Routes electrical current from power sources to various loads or sub-systems.

Signal Transmission: Carries low-voltage signals for control, feedback, and communication between components.

Organization & Safety: Reduces wire clutter, minimizes the risk of short circuits, and ensures compliance with safety standards.

Durability: Withstands mechanical vibration, temperature extremes, dust, and moisture—especially in industrial or automotive environments.

Common Wiring Harness Configurations

At Cabling Middle East, we build custom wiring harnesses to meet diverse industrial needs. Here are a few common configurations:

1. Open Bundle (Flat or Round)

-

Wires run parallel or spiraled together.

-

Common in control panels or machine tools.

2. Y-Branch Configuration

-

Main trunk with split branches.

-

Ideal for systems requiring power/signals to multiple devices.

3. Multi-Connector Loom

-

Harnesses terminating into multiple connector types.

-

Used in automotive dashboards, switchgear systems, or server enclosures.

4. Shielded Harnesses

-

Feature EMI/RFI protection using foil or braided shielding.

-

Suitable for sensitive electronics or data transmission systems.

5. Overmolded Cable Assemblies

-

Enhanced mechanical protection using injection-molded polymer at stress points.

-

Common in outdoor or mobile applications requiring high durability.

Why Quality Wiring Harnesses Matter

A well-designed and precisely manufactured harness ensures:

Consistent performance in harsh environments

Faster installation and servicing

Improved electrical safety

Reduced downtime and maintenance costs

At Cabling Middle East, we adhere to global manufacturing standards to deliver wiring harnesses that meet the highest quality and safety standards.

Conclusion

Understanding the components and configurations of wiring harnesses is key to designing systems that are both efficient and durable. Whether you’re working in switchgear manufacturing, HVAC systems, data centers, or automotive assembly, a robust wiring solution is non-negotiable.

Looking for a wiring harness partner who understands industrial complexity and delivers on time?

Contact Cabling Middle East today to discuss your custom harness requirements.

Let’s Connect

Are you in search of a reliable and experienced partner for your electrical wiring harness needs in the Middle East? Look no further! Reach out to us today or explore our website at cablingmiddleeast.com to discover how we can assist you in achieving seamless and efficient wiring solutions tailored to your requirements.

Email: vinod.hange@cablingmiddleeast.com

Mobile: +966 05 6870 8457

Get In Touch

Email: vinod.hange@cablingmiddleeast.com

Mobile: +966 05 6870 8457 | +91 702 070 4510

Address: Al-Jubail, Kingdom of Saudi Arabia