Emerging Applications of Wiring Harnesses Beyond Automotive: Aerospace, Medical, and Renewable Energy

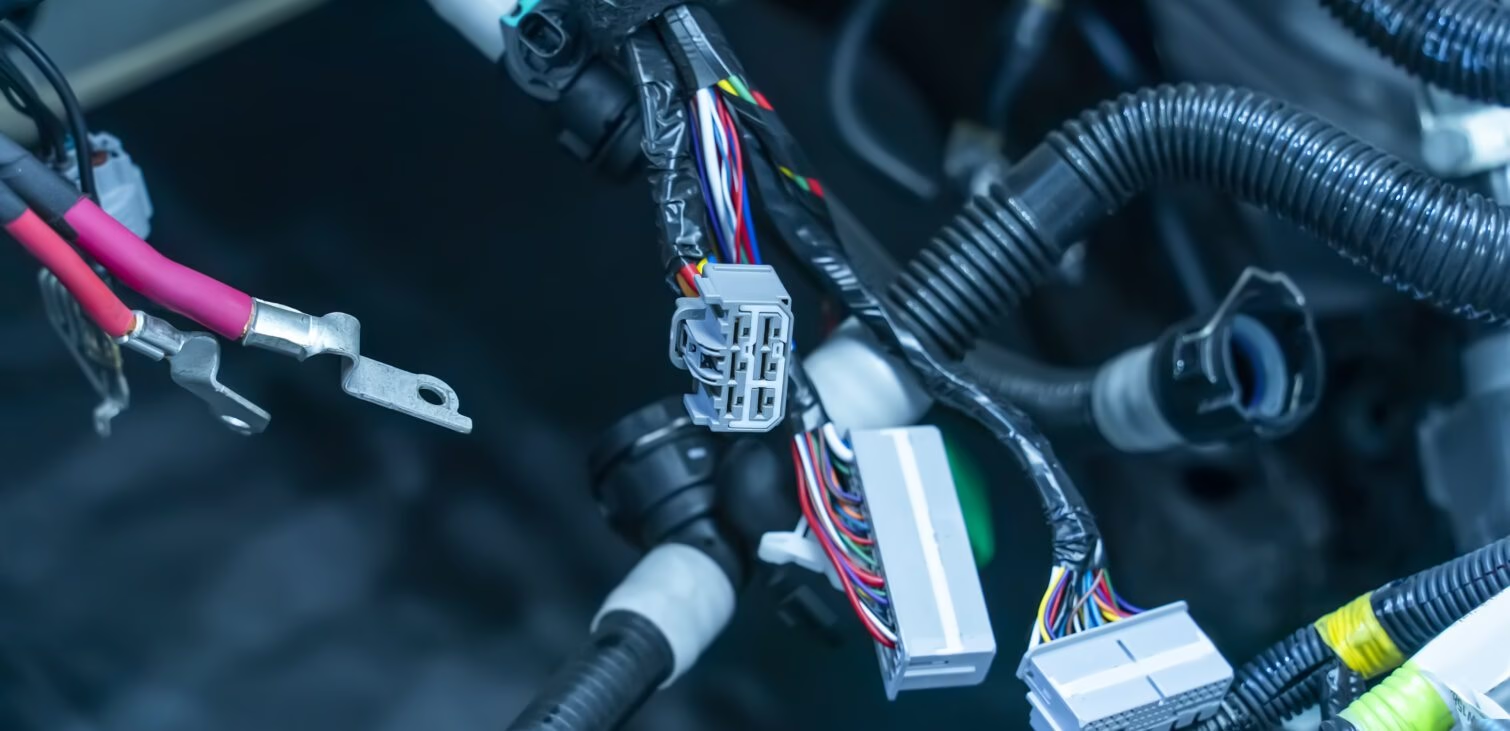

For decades, wiring harnesses have served as the backbone of the automotive industry, efficiently managing complex electrical systems. But in recent years, their role has expanded far beyond vehicles. Today, these precisely engineered assemblies are enabling progress in aerospace, medical technology, and renewable energy—industries that demand uncompromising reliability, safety, and performance.

At Cabling Middle East LLC, we specialize in designing and manufacturing custom wiring harness solutions tailored to the evolving needs of these critical sectors.

Aerospace: Precision and Performance at Altitude

In aerospace applications, every gram and every connection counts. Wiring harnesses must operate flawlessly under extreme temperatures, vibration, and pressure variations.

Key Requirements:

- Lightweight Materials: Aluminum conductors and high-performance insulations reduce aircraft weight and improve fuel efficiency.

- High Temperature & EMI Resistance: Harnesses must endure heat, electromagnetic interference (EMI), and static discharge.

- Strict Compliance: Built to meet AS9100, MIL-SPEC, and DO-160 standards.

- Avionics systems

- Engine control and monitoring units

- Cabin lighting and communication systems

- Unmanned Aerial Vehicles (UAVs)

Medical Equipment: Reliability that Saves Lives

In the medical sector, the integrity of a wiring harness can directly impact patient safety. Equipment used in hospitals, laboratories, and diagnostics must perform with absolute consistency and precision.

Key Requirements:

- Sterile and Biocompatible Materials: Harnesses often use materials that resist sterilization chemicals and high-temperature cleaning.

- Compact Design: Tight spaces in medical devices demand flexible, small-diameter cables.

- Noise-Free Transmission: Shielded wires prevent signal interference in sensitive diagnostic systems.

- Regulatory Compliance: Must adhere to ISO 13485, UL, and IEC 60601 standards.

Applications Include:

- MRI and CT scanners

- Patient monitoring devices

- Surgical robots

- Laboratory automation equipment

At Cabling Middle East, we engineer medical-grade wiring harnesses that combine miniaturization with high durability—ensuring consistent performance when it matters most.

Renewable Energy: Powering a Sustainable Future

As the world transitions to clean energy, wiring harnesses play a crucial role in connecting and managing the electrical systems behind solar, wind, and other renewable technologies.

Key Requirements:

- UV and Weather Resistance: Harnesses are exposed to heat, dust, humidity, and direct sunlight for years.

- High-Current Capability: Efficiently transmit energy generated by solar panels or wind turbines.

- Modular and Scalable Design: Supports expanding energy systems and hybrid configurations.

- Safety Standards: Compliance with IEC 62930, RoHS, and IP67/IP68 protection ratings.

Applications Include:

- Solar PV arrays and inverters

- Wind turbine control systems

- Battery storage and management units

- Smart grid connectivity

Cabling Middle East designs outdoor-rated, high-durability wiring harnesses optimized for long-term reliability and energy efficiency, helping renewable projects achieve sustainable power delivery.

The Common Thread: Customization and Quality

Across all industries, the success of a wiring harness depends on two factors: precision engineering and quality control.

At Cabling Middle East, our process includes:

- Understanding Your Application Requirements

- Design Optimization Using CAD & Simulation Tools

- Prototyping and On-Site Validation

- 100% Electrical Testing & Visual Inspection

- Batch Production with Continuous Improvement

This systematic approach ensures every harness meets its operational and environmental demands—whether it’s inside an aircraft, a hospital device, or a solar power system.

Conclusion: Harnessing Innovation Beyond Automotive

The future of wiring harnesses lies in cross-industry innovation. As aerospace, healthcare, and renewable sectors continue to evolve, so will the demand for smarter, more efficient, and more durable interconnect solutions.

At Cabling Middle East, we’re proud to contribute to this transformation—designing and manufacturing wiring harnesses that connect industries, power progress, and enable a sustainable future.

Let’s Build the Future Together

Looking for reliable wiring harness solutions for your project?

Let’s build the perfect connection.

Let’s Connect

Email: vinod.hange@cablingmiddleeast.com

Mobile: +966 05 6870 8457