The Role of Wiring Harnesses in Modern Manufacturing: From Automotive to Switchgear

In today’s fast-paced manufacturing world, efficiency, safety, and reliability are non-negotiable. Whether it’s a passenger car, a switchgear panel, or heavy industrial machinery, every system relies on a complex web of electrical connections to function smoothly. Managing these connections with loose wires is both risky and inefficient. This is where wiring harnesses step in — often described as the nervous system of modern machines.

From automotive to switchgear manufacturing, wiring harnesses have become an essential part of modern production. In this blog, we’ll explore their importance, industry applications, and why OEMs (Original Equipment Manufacturers) rely on them for consistent performance.

What Is a Wiring Harness?

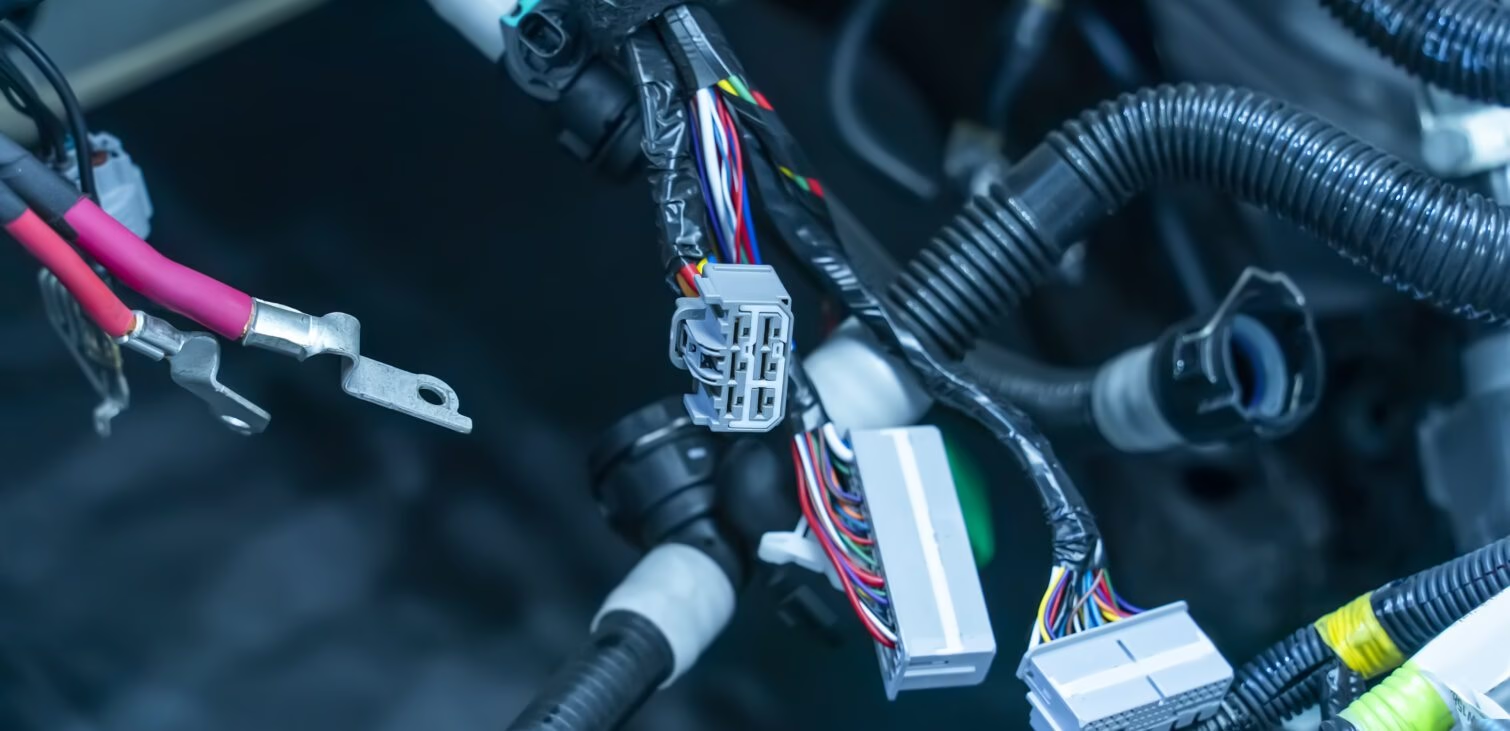

A wiring harness is an organized assembly of cables, wires, connectors, and protective coverings that route electricity or signals throughout a system.

Instead of running hundreds of loose wires, manufacturers use a harness to:

- Simplify installation (bundling wires into a single unit).

- Increase safety (reducing shorts and arc flash risks).

- Enhance durability (resisting vibration, heat, and moisture).

Example: Think of a car engine. Without a harness, every sensor, light, and switch would need separate wiring — creating chaos. A harness neatly integrates these connections into a structured, reliable form.

Wiring Harnesses in the Automotive Industry

The automotive sector is one of the largest consumers of wiring harnesses.

Traditional Vehicles

- Harnesses control everything from headlights and engine ignition to air conditioning.

- Organized harnessing ensures ease of repair and faster assembly during vehicle production.

Electric Vehicles (EVs)

- EVs demand high-voltage harnesses for battery management, charging systems, and safety features.

- Harnesses reduce weight by optimizing cable routes, improving vehicle efficiency.

- Automotive OEMs often require custom harness solutions to fit specific vehicle models.

- Harnesses are tailored to integrate seamlessly with the design while ensuring compliance with safety standards.

Wiring Harnesses in Switchgear Manufacturing

Switchgear systems are critical for power distribution and protection in industries, buildings, and utilities. The role of harnesses here is indispensable:

- Reliability & Safety: Proper harnessing reduces the risk of arc flash, overheating, and equipment failure.

- Time-Saving: Pre-engineered harnesses cut down assembly and maintenance time.

- Performance: Harnesses ensure that switchgear systems perform under high load conditions.

Example: In a power plant, switchgear harnesses help maintain safe and efficient energy distribution. A poorly routed wire can lead to downtime or even hazardous accidents.

Other Industries Benefiting from Harness Solutions

Aerospace

- Lightweight yet highly durable harnesses used in aircraft for navigation, communication, and safety.

Renewable Energy

- Harnesses in solar farms and wind turbines manage power transmission safely and reliably.

Industrial Machinery

- Heavy-duty harnesses built to withstand vibration, dust, and extreme environments.

Healthcare Equipment

- Precision harnessing ensures uninterrupted performance in life-saving machines like MRI and CT scanners.

Benefits of Wiring Harnesses in Modern Manufacturing

- Efficiency: Speeds up assembly lines by replacing hundreds of wires with one integrated system.

- Safety: Reduces risk of electrical shorts, fire hazards, and arc flash incidents.

- Reliability: Ensures long-term performance even in extreme environments.

- Customization: OEM-specific harnesses that meet unique design requirements.

- Cost Savings: Lower labor, reduced rework, and less downtime.

Example: A single wiring harness in an industrial panel can save up to 30% installation time compared to loose cabling.

Future Trends in Harness Manufacturing

Automation & Robotics

- Advanced machines are now used for cutting, crimping, and assembling harnesses — improving accuracy.

Digital Twins & CAD

- Harness designs are digitally tested before production, reducing errors.

Sustainability

- Growing use of eco-friendly insulation materials and recyclable connectors.

Smart Harnesses

- Integration with IoT and AI for predictive maintenance and real-time monitoring.

Why OEMs Trust Cabling Middle East

At Cabling Middle East, we deliver wiring harnesses that OEMs across industries rely on:

- In-House Testing: Every harness undergoes rigorous quality checks to ensure zero defects.

- Cross-Industry Expertise: Automotive, switchgear, industrial, and renewable energy sectors.

- Custom Solutions: Harnesses tailored to fit unique project requirements.

- Commitment to Safety: Designed to minimize risks of electrical failure and maximize performance.

Conclusion

Wiring harnesses are no longer just a convenience — they are a necessity for modern manufacturing. From automotive vehicles to switchgear panels, they deliver efficiency, safety, and performance at every stage of production.

At Cabling Middle East, we are proud to design and manufacture harnesses that keep industries running seamlessly.

Looking for reliable wiring harness solutions for your OEM projects? Contact Cabling Middle East today to discuss your requirements.

Let’s Connect

Email: vinod.hange@cablingmiddleeast.com

Mobile: +966 05 6870 8457

Get In Touch

Email: vinod.hange@cablingmiddleeast.com

Mobile: +966 05 6870 8457 | +91 702 070 4510

Address: Al-Jubail, Kingdom of Saudi Arabia