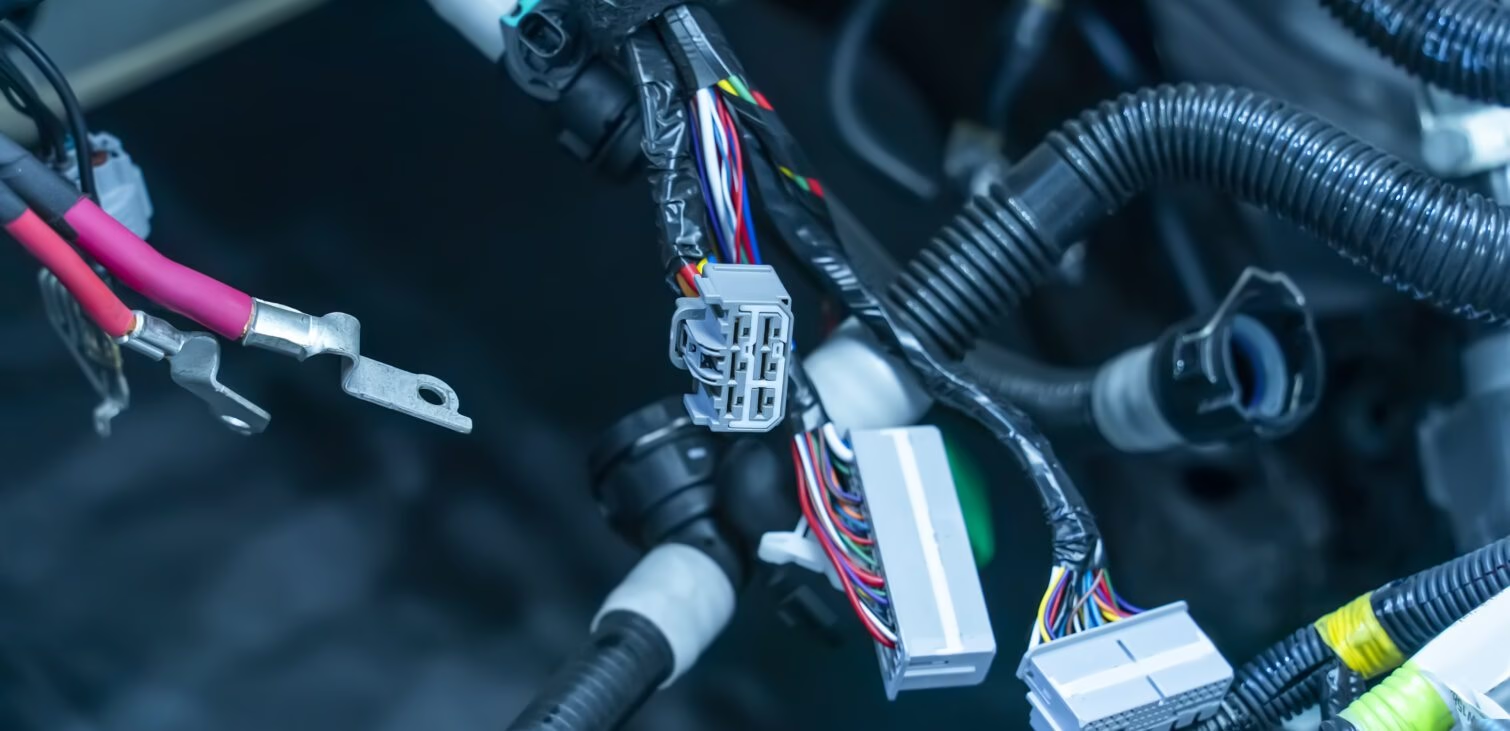

Top 7 Challenges in Electrical Wiring Harness Manufacturing – And How We Solve Them

Electrical Wiring harnesses serve as the backbone of electrical systems in various industries, including HVAC, switchgear, data center chillers, and electric vehicles. However, producing high-quality harnesses is a challenging task that requires precision, compliance, and customization. At Cabling Middle East Manufacturing Company, we have transformed these challenges into our competitive strengths.

Here are the top 7 challenges in electrical wiring harness manufacturing — and how we solve them every day.

1. Managing Design Complexity

Modern harnesses are designed to support complex systems that consist of hundreds of connections.

Our Solution:

We utilize advanced design software and 3D CAD modeling to ensure accuracy in routing, length, and connector placement. Our engineering team collaborates closely with OEMs to interpret schematics, even when provided with minimal data.

2. Ensuring Component Compatibility

Improperly matched wires, connectors, or terminals can lead to significant and costly failures. Ensuring correct compatibility is essential to safeguard your investments and maintain reliable performance.

Our Solution:

With a wealth of experience spanning over 10,000 connectors from renowned brands such as Molex, TE, Sumitomo, JST, and Kaifeng, we are dedicated to ensuring the perfect match for every application. Our meticulous part identification process has garnered the trust of global OEMs, who rely on our expertise to deliver precision and quality in every connection.

3. Material Sourcing and Traceability

Sourcing certified, durable materials that meet regional standards is a persistent challenge.

Our Solution:

We collaborate with renowned global suppliers such as RR Cable, Rolliflex, Heluka, LAPP, and Polycab, all of whom are recognized for their commitment to quality and innovation. Every raw material we source is accompanied by comprehensive certification and traceability, ensuring our products meet the highest industry standards. This includes essential certifications like UL, CE, and RoHS compliance, as well as durability ratings of IP67/68, guaranteeing robust performance in various environments.

4. Customization for Harsh Environments

Applications in the Middle East frequently encounter challenges related to heat, sand, and corrosion.

Our Solution:

We excel in providing tailored electrical wiring solutions crafted from materials that are not only heat-resistant but also waterproof and vibration-proof. Our products are meticulously designed to thrive in the harshest desert-grade industrial environments, ensuring reliability and outstanding performance even under the most demanding conditions.

5. Compliance with Global Standards

Manufacturers are required to comply with strict global and regional certification standards.

Our Solution:

Our facility is ISO 9001:2015 & ISO 14001:2015 certified. We place the utmost importance on quality and safety, which is why every product undergoes rigorous testing to ensure it meets and exceeds international electrical safety standards. This commitment to excellence guarantees that our customers receive only the highest quality products, designed with safety and reliability in mind.

6. Maintaining Consistent Quality at Scale

Achieving increased production while maintaining high-quality standards is a challenging balance to strike.

Our Solution:

We implement stringent quality control protocols and embrace lean manufacturing principles, complemented by comprehensive training for our operators at all levels. Our meticulous in-line inspection processes, coupled with thorough final-stage evaluations, guarantee that every batch we produce meets our high standards, resulting in consistently defect-free output, project after project.

7. On-Time Delivery

Delays in the harness supply can stall entire assembly lines.

Our Solution:

With local manufacturing in KSA (Al-Jubail) and strategic sourcing, we ensure timely delivery across the GCC region. Our logistics partners are optimized for fast turnaround and customs clearance.

Why Clients Choose Us

Cabling Middle East Manufacturing Company is more than just a supplier; we are your dedicated solutions partner. Our talented team of engineers and quality experts is committed to infusing every harness we create with innovation, flexibility, and unmatched reliability.

From standard assemblies to fully customized harnesses tailored to your specific needs, we leverage our expertise and advanced technology to ensure precision in every aspect of production. Our commitment to speed and compliance guarantees that you receive the highest quality products, promptly delivered to meet your operational requirements. Let’s build the future together with the utmost craftsmanship and attention to detail.

Let’s Connect

Are you in search of a reliable and experienced partner for your electrical wiring harness needs in the Middle East? Look no further! Reach out to us today or explore our website at cablingmiddleeast.com to discover how we can assist you in achieving seamless and efficient wiring solutions tailored to your requirements.

Email: vinod.hange@cablingmiddleeast.com

Mobile: +966 05 6870 8457

LinkedIn: Cabling Middle East Manufacturing Company

Explore More Articles!

1. From Design to Delivery: How Custom Harness Are Manufactured: https://cablingmiddleeast.com/from-design-to-delivery-how-custom-harness-are-manufactured/

2. Driving Localization in the Kingdom of Saudi Arabia: Our Commitment to Vision 2030: https://cablingmiddleeast.com/driving-localization-in-the-kingdom-of-saudi-arabia-our-commitment-to-vision-2030/

Get In Touch

Email: vinod.hange@cablingmiddleeast.com

Mobile: +966 05 6870 8457 | +91 702 070 4510

Address: Al-Jubail, Kingdom of Saudi Arabia